Well, I guess, with almost 'specific' Reference to the Brass bit,.., Especially Larger/Thicker 'Chunks' of it,...

It's Pretty Damn Hard to go Past The Good Old Tried, Trusty and True WELLER 80 Watt unit, such as this;

- weller-sp80d-marksman-soldering-iron-80watt-240-volt-50-hertz.jpg (44.02 KiB) Viewed 23239 times

In fact, a Quick Ebay search, returned This unit, at what one Could easily argue, is a pretty Damn Good Price !!

See here;

http://www.ebay.com.au/itm/Weller-Solde ... XQfvlSnBx9

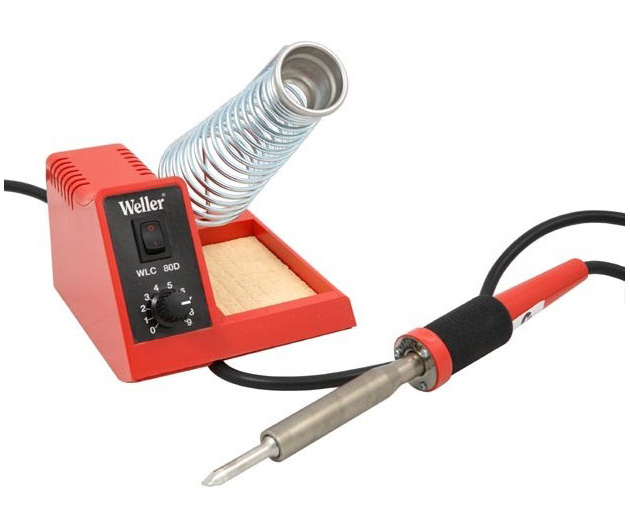

I have noticed this Series/Rating of Iron, is Also available as a 'Station' style unit, with Adjustable Temp and integrated Stand etc, which looks pretty good.

- weller-wlc80d-marksman-soldering-iron-80-watt-leadlight-station-and-pencil.jpg (67.14 KiB) Viewed 23239 times

I Have used the Slightly Smaller 'Tip' as shown fitted on the 'Station' unit above and would suggest Would work very well with the Adjustable Temp', but have found the Larger 'Tips' work Better? in the Stand-Alone unit. They have a Good Surface Are on the 'Tip' to transfer plenty of Heat !!,..

They DO Require a Degree of Care, like Always keeping a Wet Sponge available to keep the 'Tip' Clean etc.

I have used these for Years and am pretty sure is the Same unit that Fox has/uses as well !!

I have a feeling I also have a 'Nicholson' branded device which is intrinsically the Same, although the 'Tips' are Not interchangeable.

When attempting to Solder ANY Thick/Larger Lumps O' Brass,... there is NO Substitute for a 'Mutha' of an Iron that can Actually 'Apply' heat, instead of having the Brass act as a Heat Sink and actually 'Cooling' the Iron !!!!..lol

Starting with Well Prepared Sanded and Clean 'bits' and using a GOOD (Acid) Flux !!

The 'Yanks', ALL seem to be Sold on 60/40, but I was SOLD on the 'concept' AND Use of good Old "Plumbers Stick" 50/50 !!, by Hutcho', Waaay back and is what I would imagine Foxy still uses as well.

In fact, whilst 60/40 CAN be used, it Was in fact 'Designed' to Exhibit Properties that DO work Far better for general electronics work, ie; that it can form Nice 'Blobbed' Joints etc,.. whereas (as one could possibly imagine, when considering it's Name), 50/50, exhibits a Greater ability to 'Flow' and provides a Very Nice finished Joint, with good Plasticity and Service life !!

Personal FLUX Likes, Uses and Dislikes vary Greatly !!,..LOL

I'm Still using some stuff that I tracked down to the Dude who Actually 'Originally' created it, (also Via a Hutcho' referral) and is Now available, as EZI-WELD 801.

It IS a VERY 'Capable' and Excellent Flux,.. in some ways, Hard to Beat/Go Past,... BUT,....

The stuff IS "Aggressive" !!,... 'Things', DO Require GOOD Cleaning afterwards AND During !!,.. lol

Personally, I really Don't Mind having to do that, as part of my building Process.

Fox used to use it as well, although I am pretty sure he has found and is using a Different and Obviously 'effective' Flux, that is Less Aggressive than the 801.